Insulating the Foundation for a High Performance House

Foundation Insulation

Imagine stepping barefoot onto the floor in your basement - your body is immediately flooded with chills.

With traditional homes, that’s likely the case but we’ve developed a strategy to maintain a comfortable temperature in the basement of this high performance home all year long.

From the construction site of a new high performance home, David Schleicher explains in the video below how we isolated the foundation in order to build a more comfortable, durable, sustainable, and healthy home from the ground up.

Inside of the 9 ft tall foundation walls, we installed 4 inches of EPS foam on top of 8 inches of compacted gravel with the seams staggered to minimize heat loss.

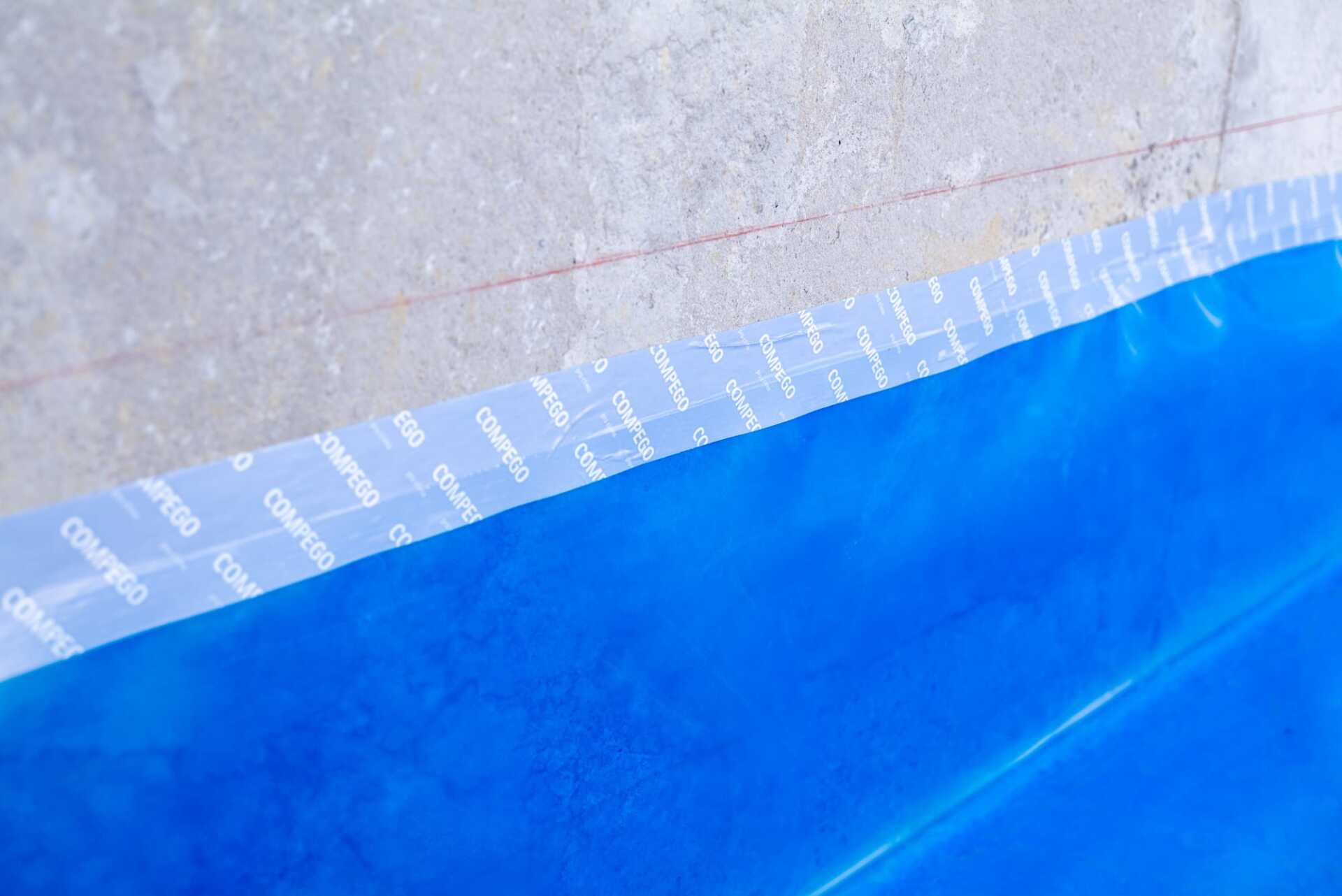

Above the foam we installed our air/vapor barrier: a 15 mm plastic sheet that we ran 1 foot up the walls and taped with Compego Tape along the foundation walls. The foundation wall serves as the air barrier from the foundation wall to mud sill. All of the plastic is taped, including penetrations for the floor drainage.

An additional measure that we like to do on a job site is to transcribe the wall details on the foundation wall so all parties involved have a visual - this helps to minimize the potential for errors at this crucial step in construction.

As our final step to creating a well insulated basement floor, we pour the concrete making sure that timing lines up with the installation of our air/vapor barrier. If we install the 15 mm plastic too soon it will shrink with exposure to the elements. Our goal is to install the plastic and pour concrete the next day.

At the end of this process, we have a system that isolates all concrete from directly touching other layers of concrete.