Air Sealing at Its Finest

Air Sealing at a West Plaza High Performance House

Joe Nickels and Brandon Brown have been working on air sealing at the Fairmount High Performance House this week. Joe is one of the only certified dealers qualified to use AeroBarrier in Kansas City. It is safe to say most builders in the area are skipping this integral step in the building process altogether.

Sure, it’s easy enough to locate large holes in the building envelope. Those aren't the holes we are concerned about filling here. You’ve heard the phrase “death by a thousand cuts.” Those smaller holes in the envelope are what we are looking for in this sealing process.

It’s crucial to seal those small holes to create a truly airtight envelope.

AeroBarrier is an aerosol sealant used to fill gaps in the envelope smaller than ½ inch. Those tiny holes can make or break the envelope. The process of air sealing involves a blower door to pressurize the home and finely tuned nozzles to spray the sealant throughout the interior of the home.

AeroBarrier sealant is a non-toxic, water based formula that is GreenGuard Gold certified with Ultra-low VOC content and no off-gassing. While you don’t want to be inside the home during the sealing, it’s safe to resume work 30 minutes after the process is complete.

How the Air Sealing Process Works

The process of air sealing is fairly straightforward.

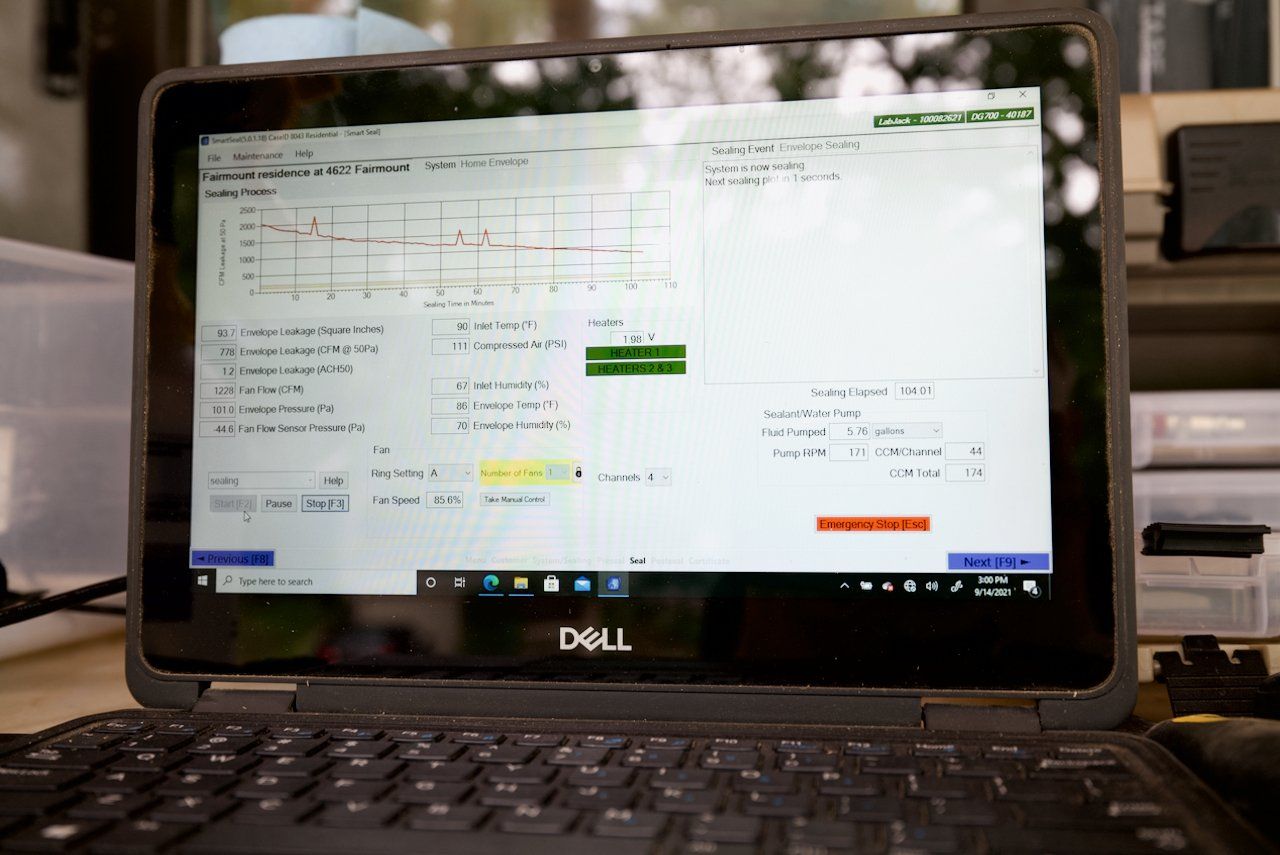

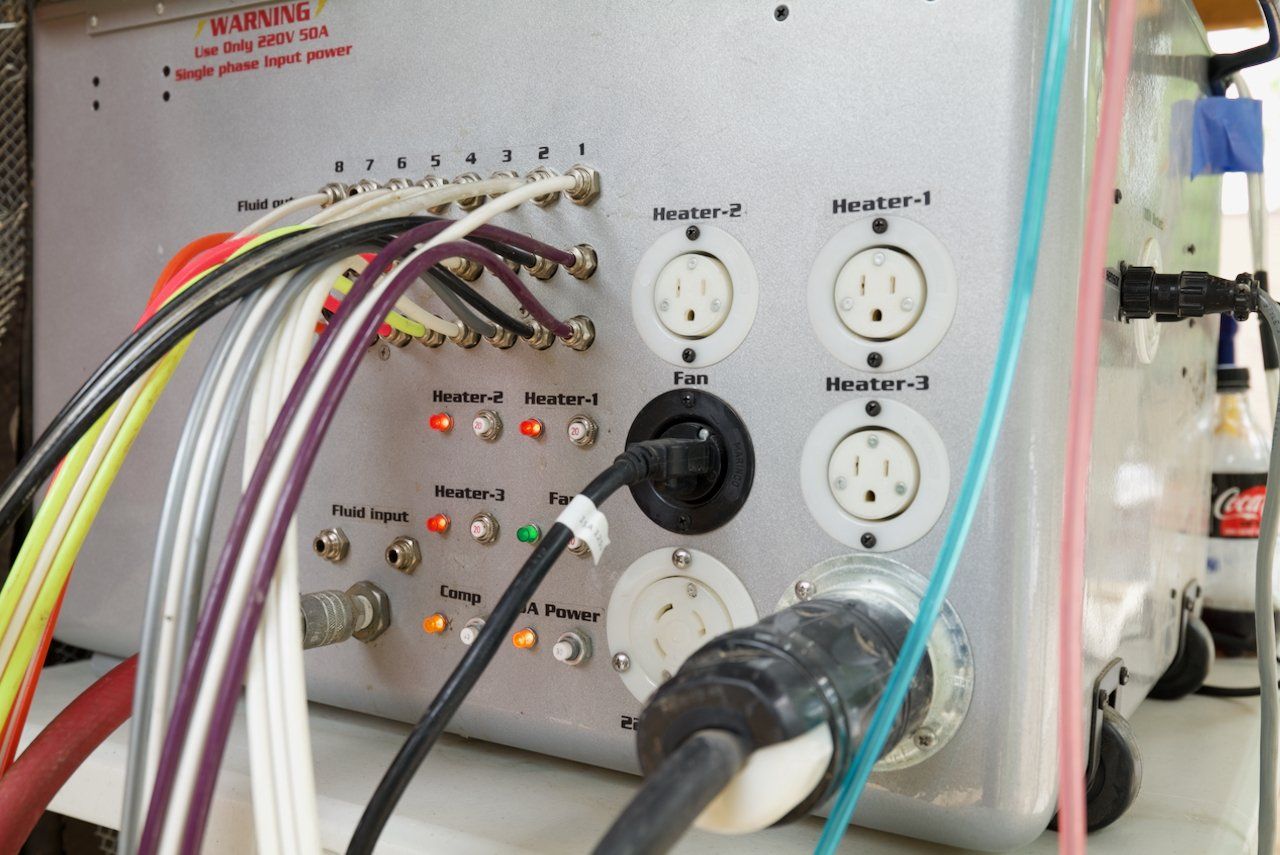

We start out by covering up openings that won’t be sealed during the application. After the larger holes are covered up, we then set up the AeroBarrier Connect System: blower door, nozzles, hoses, fans, and the computer control system.

The space is then pressurized using a blower door and then the computer control system runs the remainder of the process. Temperature, pressure, humidity and the application are all controlled by the computer system. Once everything is set up and running properly, we can see the airtightness results in action through the control panel.