Thermal Bridging

What is a thermal bridge, and why are they so bad?

A thermal bridge is a penetration in the insulation layer with a highly conductive material, allowing increased amounts of heat flow through that material. This is a problem – a BIG problem. Energy bills are increased, interior comfort is reduced, and the building’s integrity is compromised.

Sadly, thermal bridges are all around us. Chances are your home or office is full of them! For example, exposed concrete balconies are a very common thermal bridge in typical construction. The concrete slab extends out to the exterior air from the interior space. We spend money to keep that interior air warm in the winter, and cool in the summer, but then unnecessarily design our buildings to lose or gain heat.

Another classic example is a structural stud, or even worse, a metal stud! Many designs expose one side of the stud to the interior, and one to the exterior. That is very bad. The standard 2×6 wood framed wall with R19 batt insulation is more realistically a R13, and if metal studs are used, you can count on an R9.

Thermal bridging matters! It matters a lot, and not just for energy loss.

Have you ever stood beside a cold interior surface in your home or office? We all have, especially in January. Thermal bridges cause these cold interior surfaces. Cold interior surfaces cause mold, mildew, and eventually decay. Yes, mold. If surface temperatures are below the interior air’s dew point temperature, then we get condensation. Continuous condensation is a serious problem for the interior occupants’ health, comfort, and the building’s integrity. Common locations for this are:

- Around low quality windows & doors

- Interior corners

- Behind furniture

- Where the building is in contact with the ground

- Rim joists

- Roof connections to the wall

- Concrete balcony penetrations through the wall

- Voids in the insulation layer

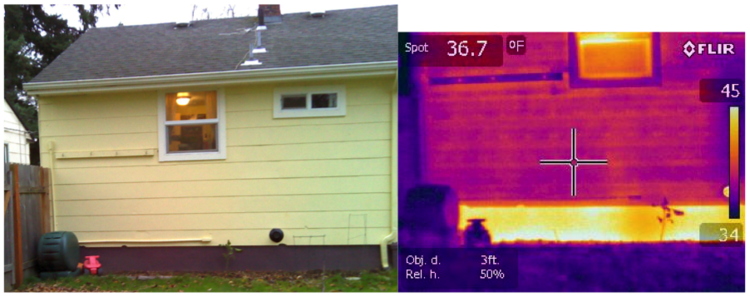

Image 1: Concrete foundation thermal bridge (Image Source: Sam Hagerman, Thermal Bridge Free Construction)

In image 1, tremendous thermal bridging is seen with the glowing from the foundation basement wall. That is a lot of energy being lost! There’s no use in heating up your backyard. This is a common reason why basements smell ‘musky.’ That’s because so much heat is lost through uninsulated foundation walls and slabs, reducing interior surface temperatures, and allowing condensation to accumulate over time. Bad news.

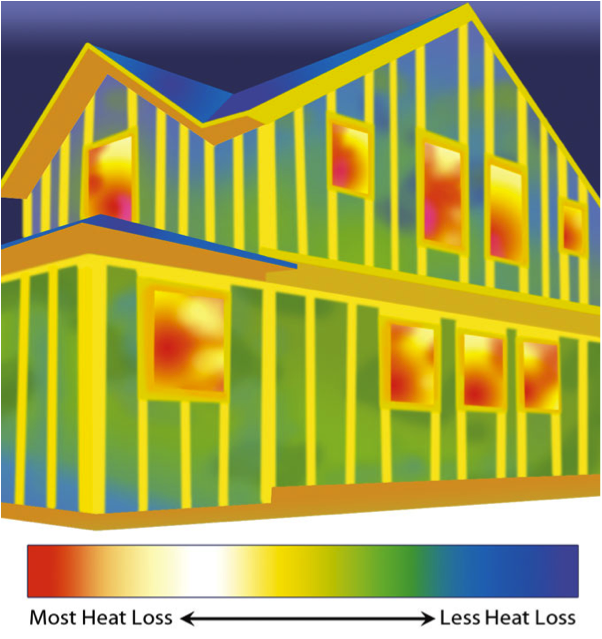

Image 2: Schematic drawing of thermal bridging in a house (Source)

In image 2, a schematic representation of what thermal bridging looks like in a typical residential house. The yellow at the studs, and the rim joist locations is not a pretty color for a building scientist, or a home owner. Even worse, the low quality windows outlined in red represent even more heat loss, low interior surface temperatures and an increased potential for forming interior condensation. We should strive for all exterior surfaces to be cold, and interior surfaces to be warm.

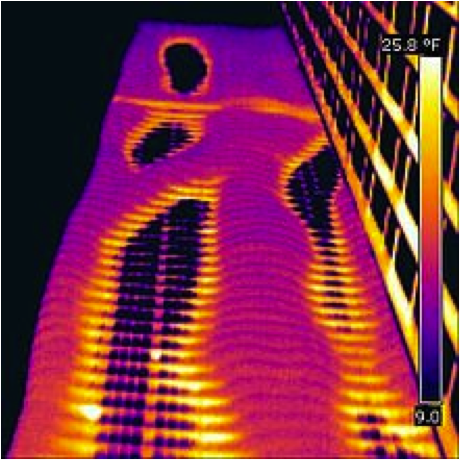

Image 3: Agua Tower thermal bridge of concrete balcony. (Source)

Image 3 is represents a modern disaster of building science. This is a fairly new building in Chicago. Those are concrete balconies that extend from the interior space to the exterior air (known as “highways of heat loss”). That is energy being wasted because of careless design. That is putting the occupants’ health at risk because of potential mold growth due to condensation – very poor design, indeed. This is a new building, yikes! Where was the building scientist? We know better than that!

Read more about this building and solutions for the problem.

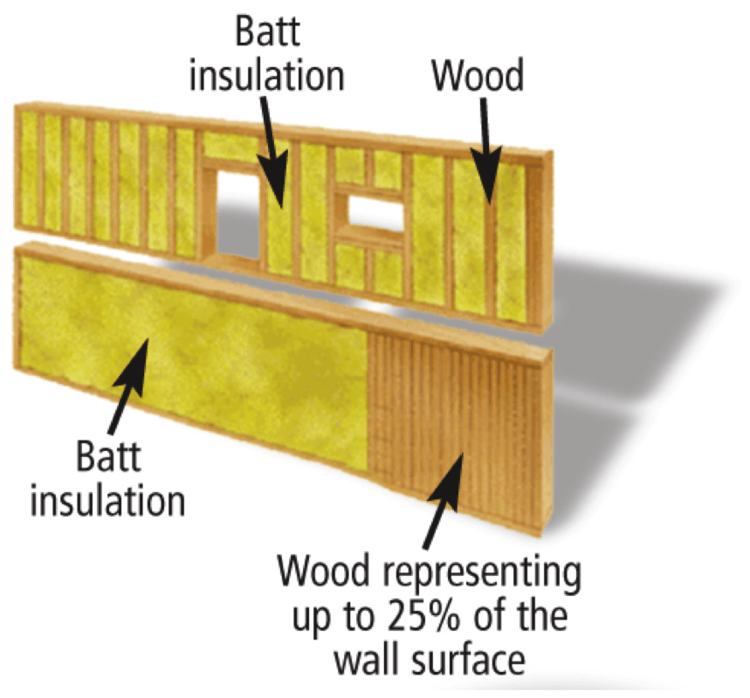

Image 4: Represents the thermal bridges in framing (Image Source: Sam Hagerman, Thermal Bridge Free Construction)

Image 4 is a great representation of how much framing studs are in typical construction. Each one of those studs will allow more heat loss than the insulation. This needs to be accounted for! Next time you hear, ‘Oh, my wall is an R-19!’ Ask them if that includes all of the framing? Chances are it does not, and it makes a very big difference. Most ‘R-19′ walls are more like an R-10 to R13 range, depending on how much framing was used. That is a 30% to 50% change in thermal resistance, that’s no joke.

Image 5: Example of a void in the insulation (Source: Sam Hagerman, Thermal Bridge Free Construction)

Image 5 displays a void in the insulation layer. Although not a ‘thermal bridge,’ it does produce the same negative effects: Reduced overall R-value, reduced interior surface temperatures, increased heat loss, reduced interior comfort, and structural durability – none of which are good things. Please do not have voids in your insulation layers. Voids allow for air to move in the framing cavity. This is very bad. It reduces R-value due to increased convection heat transfer. Voids also increase the potential of moisture entering the cavity due to increased air movement. This is a problem most commonly found in batt insulation systems. Either use great care when installing insulation batts, or use blown in insulation to ensure all voids are filled.

That is probably enough thermal bridge images for one day. We imagine that you now get the picture of what exactly a thermal bridge is, and why it is important to completely avoid them in your building design.

Avoid such problems & Design and Construct Thermal Bridge free!

Best practices for thermal bridge free construction:

- Use continuous insulation on the exterior side of framing, without voids

- Reduce framing in the wall

- Use thermally broken joints in balconies

- Use high performance windows and doors

- Use thermally broken foundation assemblies

- No penetrations through the insulation layer with highly conductive materials

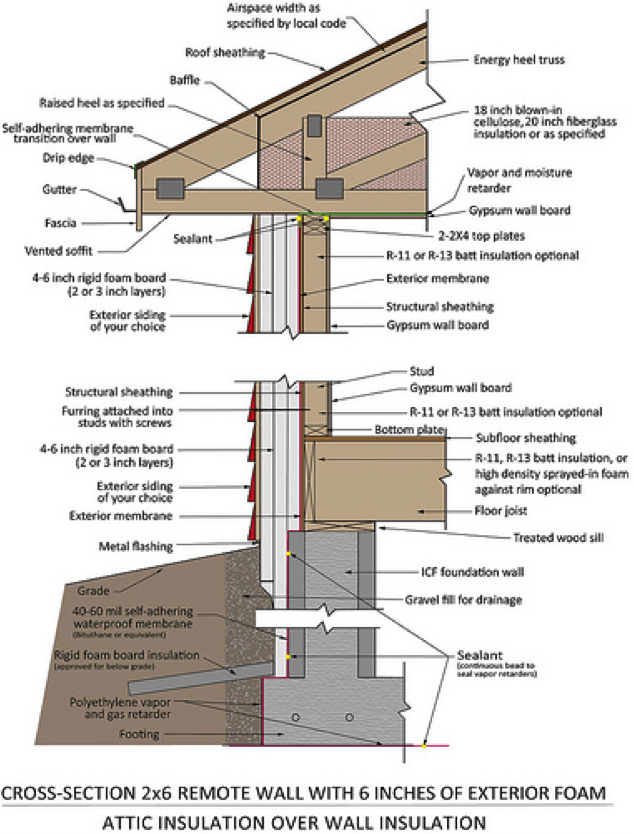

Image 6: Example of Exterior insulation (Source)

In image 6, an example of exterior insulation is displayed from our friends at the Cold Climate Housing Research Center in Northern Canada. These guys know a thing or two about controlling heat loss! On the outside of the structural framing studs, several layers of rigid foam insulation are used to reduce thermal bridging through the framing. Very nice work! This forms a continuous insulation layer that keeps interior surface temperatures high and interior comfort high. This is essential for high performance construction.

Remember, thermal bridges must be limited not only because of energy loss, but also for reasons related to structural integrity and interior comfort!